MAN Euro 6 Technology | A TruckLocator review

Posted On: Saturday 11 August 2012

To reach Euro 6 standards, MAN has used two proven technologies working together.

MAN Trucks has already been using the key technologies necessary for Euro 6 - EGR (exhaust-gas recirculation), diesel particulate filter and SCR (Selective Catalytic Reduction) - in commercial vehicles with great success for several years. SCR technology, for example, has been installed as standard in trucks since 2005. MAN's particulate filter technology CRTec has been in series operation since as far back as the year 2002. A further reduction in fuel consumption was a primary goal for the developers.

The Euro VI vehicles are particularly efficient and reliable transport solutions, just like those our customers are already familiar with in our EEV-compliant trucks and buses with their deserved reputation for economy. This is expressed by the claim for the new truck generation: "Euro VI is coming, efficiency is here to stay." The Euro VI engines are also distinguished by the well-known dynamic characteristics, with power and torque corresponding to the EEV-compliant engines.

MAN's Euro 6

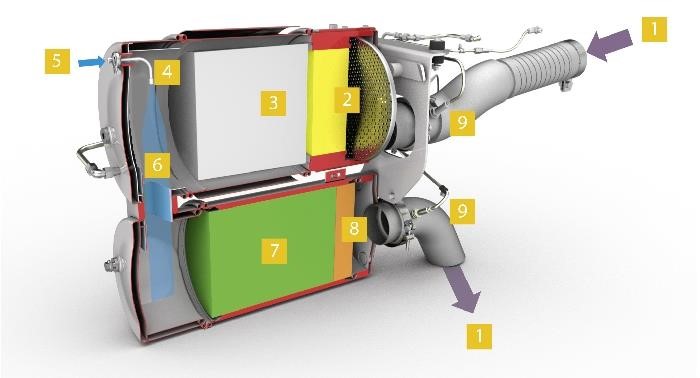

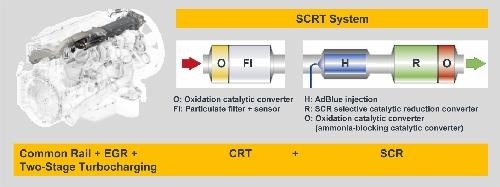

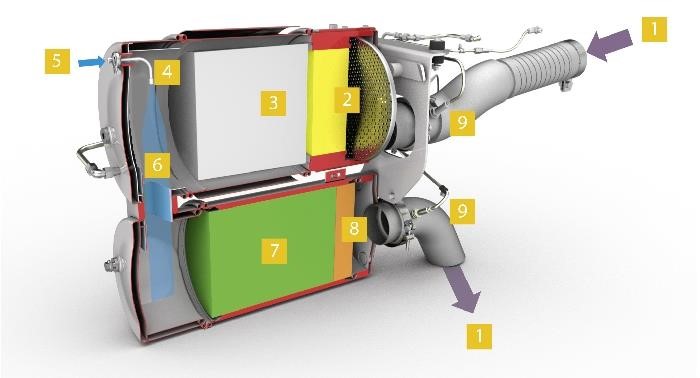

For this reason, the most important success factor in the Euro VI development was unifying two goals with opposed physical principles: the reduction of NOx and the reduction of fuel consumption and consequently of CO2 emission. MAN has been able to reduce the fuel consumption of its engines continually over the past few years, while at the same time meeting the ever more stringent requirements regarding nitrogen oxide reduction. For the leap from Euro V / EEV to Euro VI, the MAN developers have optimised injection and combustion with regard to consumption and production of particulate. In the course of the series-production and field tests, exact data on consumption has been and continues to be collected. The Euro VI trucks and coaches will be just as efficient in terms of fuel consumption as the generation of vehicles equipped with EEV-compliant engines. As far as city buses are concerned, the introduction of Euro VI technology has not only decreased emissions significantly but has even reduced fuel consumption by an average of between three and five percent across all the engine variants. With effect from January 1, 2014 all newly registered vehicles must comply with the Euro VI exhaust-gas standard. By comparison with the Euro V standard, Euro VI requires a reduction of 80 percent in NOx emissions, from 2 g/kWh to 0.4 g/kWh. MAN achieves this with a combination of controlled and cooled exhaust-gas recirculation and an SCR catalytic converter for exhaust-gas aftertreatment. Dividing the workload between the two systems, EGR and SCR, is the optimum solution for low fuel consumption paired with low AdBlue® consumption. Controlled EGR enables low raw emissions of NOx. This in turn means low AdBlue® consumption for NOx reduction in the SCR system. MAN's concept is distinguished by low fuel consumption, low AdBlue® consumption and high reliability. Compared with Euro VI, the particulate mass has to be reduced by a further 66 percent. In addition, Euro VI stipulates for the first time a limit on the number of particles. The only way to comply with these limit values is by the use of closed particulate filters, which in practice leads to a 90-percent reduction of the particulate mass by comparison with Euro V. This is why MAN combines the SCR catalytic converter with a closed particulate filter, an oxidation catalytic converter and the associated sensors to form the SCRT system, whose compact dimensions enable it to fit neatly into the silencer. The reduction in nitrogen oxide emissions required by Euro VI is roughly as much as in all five previous stages of the Euro standard together. In Euro VI, the systems will for the first time have to continuously monitor compliance with limit values in operation ("in-use compliance"). The expanded requirements regarding the in-use monitoring of NOx necessitate new, more complex vehicle electronic systems and sensor.

The two turbochargers have been combined to form a single compact turbocharger module. Each stage is equipped with a waste gate. This makes it possible to control boost pressure and distribution between the two stages so that the energy of the exhaust gas is used most effectively. The high-pressure stage, a small exhaust turbocharger with waste gate, ensures speedy build-up of boost pressure and thus high pulling-away torque in the lower load and engine-speed range. Even at low engine speeds the high air ratio is produced that is required for combustion with low particulate content. In the upper load and engine-speed range, the low-pressure stage ensures the necessary amount of air and is characterised by especially high efficiency, resulting in very good fuel consumption and combustion with low particulate levels. This turbocharging strategy not only helps the Euro VI engines also produce the pulling power at all engine speeds for which MAN is renowned, it is also consciously based on two separate rugged and reliable turbochargers instead of more complex turbochargers with variable turbine geometry.

The Euro VI engines in the TGL series delivering 110 kW / 150 hp and 132 kW / 180 hp employ single-stage turbocharging at the same high level of efficiency. The basic design of the engine and stroke and bore have not changed. Cooled exhaust-gas recirculation (EGR) has been in series production at MAN since 2000. The recirculation of cooled exhaust gases makes a low peak combustion temperature possible. As a result, fewer nitrogen oxides are formed. Euro VI utilises electronically-controlled EGR, which ensures considerably improved control performance. Thanks to EGR control with its lambda probe, the optimal EGR rate is set for each operating point of the engine even in dynamic conditions. This guarantees a particularly high level of efficiency and economical fuel and AdBlue® consumption. The newly developed SCRT system used for exhaust-gas aftertreatment combines an oxidation catalytic converter, a closed, electronically controlled surface particulate filter and an SCR catalytic converter with AdBlue® injection. MAN has been using the particulate filter component as CRTec® filter since as far back as 2002. AdBlue has a freezing point of minus 11.5 degrees Celsius. For this reason the tank, the supply lines and the AdBlue® dosing module can be heated, ensuring that exhaust gases are properly cleaned even at low ambient temperatures. Euro VI legislation means that on-board diagnosis has to provide several more functions; the electronics now has to permanently monitor the emission values. In the event of a fault, OBD informs the driver by means of a warning indicator. In addition and independently thereof, Euro VI legislation stipulates an NOx control system ("anti-tampering"). This system monitors the SCR system, checking that it is supplied with AdBlue® in the specified amount and quality. If this is not the case, a warning is initially output to the driver. This escalates to a reduction of torque, and in a third step to a speed restriction. Beforehand, i.e. also from a cold start and during light-loading operation, the limit values as per the "Worldwide Harmonized Duty Cycles" must be complied with. Moreover, the emissions must be guaranteed to be stable for 700,000 kilometres or seven years. This shows clearly just how comprehensive the development and product requirements for Euro VI vehicles are.

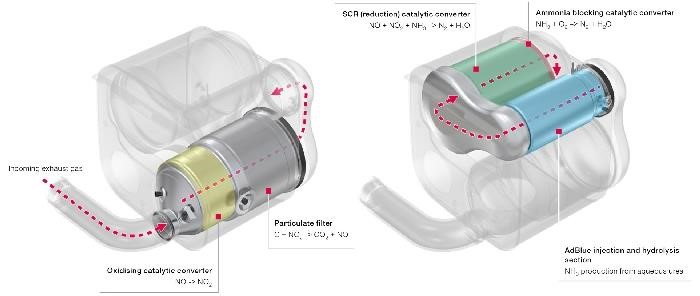

Simplified, the SCRT system functions as follows. First, an oxidation catalytic converter with a highly efficient precious-metal coating converts the limited constituents of the exhaust gas, HC and CO, to harmless CO2 and H20. The nitrogen oxides are also largely converted from NO to NO2. The surface particulate filter (CRT) that follows traps up to 99 percent of the particulate mass present in the exhaust-gas stream. The soot particles trapped in the CRT filter are catalytically burned using the NO2 produced beforehand and thus converted to CO2. The soot loading on the particulate filter is electronically monitored by sensors. This information helps to control regeneration of the filter. Continuing the process, with the help of the injected reducing agent AdBlue® the SCR catalytic converter reduces the amount of nitrogen oxide to below the Euro VI limit of 0.4 g/kWh. In combination with EGR and turbocharging, the SCR process enables the engine's combustion to be designed for low particulate levels. This made it possible for MAN's engine designers to also realise consumption-optimised combustion. The nitrogen oxides formed during combustion are then treated by selective catalytic reduction with the help of the additive AdBlue®, which is injected as required upstream of the SCR catalytic converter. The last element that the exhaust gas flows through is an ammonia-blocking catalytic converter. This converts any residual amounts of the reduction agent NH3 (ammonia) necessary for the SCR catalytic converter into nitrogen and water. Regeneration: highest levels of reliability and safety In formulating its regeneration strategy for the diesel particulate filter, MAN paid special attention to maximum operational reliability. Regeneration of the particulate filter takes place automatically during normal operation without any action having to be taken by the driver. This permanently running passive regeneration ensures that the particles (carbon C) trapped by the filter material are converted to CO2 and do not clog the filter. Regeneration in the TGX, TGS and coach is designed to be carried out by a passive SCRT system. In normal driving operation, the system functions at exhaust-gas temperatures at which regeneration permanently takes place. Special regeneration phases or supplementary injection of fuel to raise the temperature are not necessary during normal operation. If the vehicle spends a lot of time idling or is operated in short-distance transport, the system has other modes that enable it to perform regeneration while on the go.

Regeneration: highest levels of reliability and safety In formulating its regeneration strategy for the diesel particulate filter, MAN paid special attention to maximum operational reliability. Regeneration of the particulate filter takes place automatically during normal operation without any action having to be taken by the driver. This permanently running passive regeneration ensures that the particles (carbon C) trapped by the filter material are converted to CO2 and do not clog the filter. Regeneration in the TGX, TGS and coach is designed to be carried out by a passive SCRT system. In normal driving operation, the system functions at exhaust-gas temperatures at which regeneration permanently takes place. Special regeneration phases or supplementary injection of fuel to raise the temperature are not necessary during normal operation. If the vehicle spends a lot of time idling or is operated in short-distance transport, the system has other modes that enable it to perform regeneration while on the go.

Whenever necessary, the "Soft Active" mode uses a secondary-injection function of the common-rail system to raise the temperature of the exhaust gas. This is automatic and does not require any action on the part of the driver. As a further option, the system is able to perform idle regeneration, which can be initiated and ended manually by the driver. Here, the engine carries out a special regeneration program that creates the exhaust-gas temperature necessary for degrading the exhaust-gas particles and regenerating the filter. The engine variants installed in the TGL and TGM series are fitted as standard with active SCRT systems for regeneration of the diesel particulate filter and are thus optimally equipped to meet the demands of distribution transport. This system also functions in normal driving operation without a special regeneration program, that is, it functions with the available exhaust-gas temperatures. In the event of additional self-cleaning becoming necessary, the system causes the exhaust-gas temperature to be raised in several stages. The TGL and TGM also permit idle regeneration initiated by the driver. Due to the typical driving cycles in city buses, these vehicles are fitted with fully passive SCRT systems. The Euro VI diesel particulate filter is regenerated at the temperature of the exhaust gas produced by the engine. In every vehicle, an electronic system monitors the controlled process, the protection of the engine and the components of the exhaust-gas aftertreatment system. Regeneration enables the degradation of almost all particulate while the vehicle is being operated. The residue present after several hundred thousand kilometres can be removed by changing the filter element during servicing. The vehicle's service interval calculator recommends the intervals between cleaning, taking into account the operating conditions and the continually monitored exhaust-gas backpressure. Arrangement and structure of the exhaust-gas silencer are designed for time-saving and thus cost-efficient removal and installation by Service outlets.

MAN has arranged the Euro VI components in compact form. As has been the case up to now, no parts project above the frame top edge, guaranteeing maximum flexibility for mounting bodies. The AdBlue® tank is a separate, heated tank and is located on the left side of the vehicle. MAN designed the AdBlue® tanks this size so one tankful would provide sufficient range for two tankfuls of diesel fuel. All the variants of the exhaust pipe that have been available up to now will continue to remain available for Euro VI vehicles. The new arrangement of the add-on parts means that the same amount of space on the frame is free for tanks on both sides of the vehicle. The Euro VI system in the TGL and TGM series With the advent of Euro VI, SCR is for the first time being installed in TGL and TGM vehicles, where it supplements the proven EGR technology. The basis is formed by the Euro V / EEV engines, which have been produced in series since 2009.

EGR with demand-controlled recirculation rate and the common-rail system with 1,800 bar injection pressure are the backbone of the Euro VI system in the engine itself. The power spectrum ranges from 110 kW / 150 hp to 251 kW / 341 hp. Engines delivering 162 kW / 220 hp and above are fitted with two-stage turbocharging and boost-air intercooling. The TGL and TGM series meet the Euro VI standard by means of a more compact combination of oxidation catalytic converter, particulate filter and SCR, also completely integrated in the rear silencer on the right side. The task of particulate cleaning is taken over by electronically monitored ceramic filter elements. Free installation space on the right side of the vehicle remains unchanged. The AdBlue® tank is a separate, heated tank and is also located on the right side of the vehicle. The size of the AdBlue® tanks for TGL and TGM is similarly designed for two tankfuls of diesel fuel. MAN TGL and TGM trucks enable outstandingly big payloads even in Euro VI and are among the lightest in their class. The Euro VI system makes the four-cylinder vehicles around 100 kg heavier, the six-cylinder vehicles around 150 kg.

MAN Trucks has already been using the key technologies necessary for Euro 6 - EGR (exhaust-gas recirculation), diesel particulate filter and SCR (Selective Catalytic Reduction) - in commercial vehicles with great success for several years. SCR technology, for example, has been installed as standard in trucks since 2005. MAN's particulate filter technology CRTec has been in series operation since as far back as the year 2002. A further reduction in fuel consumption was a primary goal for the developers.

The Euro VI vehicles are particularly efficient and reliable transport solutions, just like those our customers are already familiar with in our EEV-compliant trucks and buses with their deserved reputation for economy. This is expressed by the claim for the new truck generation: "Euro VI is coming, efficiency is here to stay." The Euro VI engines are also distinguished by the well-known dynamic characteristics, with power and torque corresponding to the EEV-compliant engines.

MAN's Euro 6

For this reason, the most important success factor in the Euro VI development was unifying two goals with opposed physical principles: the reduction of NOx and the reduction of fuel consumption and consequently of CO2 emission. MAN has been able to reduce the fuel consumption of its engines continually over the past few years, while at the same time meeting the ever more stringent requirements regarding nitrogen oxide reduction. For the leap from Euro V / EEV to Euro VI, the MAN developers have optimised injection and combustion with regard to consumption and production of particulate. In the course of the series-production and field tests, exact data on consumption has been and continues to be collected. The Euro VI trucks and coaches will be just as efficient in terms of fuel consumption as the generation of vehicles equipped with EEV-compliant engines. As far as city buses are concerned, the introduction of Euro VI technology has not only decreased emissions significantly but has even reduced fuel consumption by an average of between three and five percent across all the engine variants. With effect from January 1, 2014 all newly registered vehicles must comply with the Euro VI exhaust-gas standard. By comparison with the Euro V standard, Euro VI requires a reduction of 80 percent in NOx emissions, from 2 g/kWh to 0.4 g/kWh. MAN achieves this with a combination of controlled and cooled exhaust-gas recirculation and an SCR catalytic converter for exhaust-gas aftertreatment. Dividing the workload between the two systems, EGR and SCR, is the optimum solution for low fuel consumption paired with low AdBlue® consumption. Controlled EGR enables low raw emissions of NOx. This in turn means low AdBlue® consumption for NOx reduction in the SCR system. MAN's concept is distinguished by low fuel consumption, low AdBlue® consumption and high reliability. Compared with Euro VI, the particulate mass has to be reduced by a further 66 percent. In addition, Euro VI stipulates for the first time a limit on the number of particles. The only way to comply with these limit values is by the use of closed particulate filters, which in practice leads to a 90-percent reduction of the particulate mass by comparison with Euro V. This is why MAN combines the SCR catalytic converter with a closed particulate filter, an oxidation catalytic converter and the associated sensors to form the SCRT system, whose compact dimensions enable it to fit neatly into the silencer. The reduction in nitrogen oxide emissions required by Euro VI is roughly as much as in all five previous stages of the Euro standard together. In Euro VI, the systems will for the first time have to continuously monitor compliance with limit values in operation ("in-use compliance"). The expanded requirements regarding the in-use monitoring of NOx necessitate new, more complex vehicle electronic systems and sensor.Main components of the Euro 6 technology

The central components for Euro VI are, on the engine side, common-rail- injection, cooled and controlled exhaust-gas recirculation and two-stage turbocharging. These are followed by exhaust-gas aftertreatment by an SCR system with integrated oxidation catalytic converter plus CRT filter (Continuously Regenerating Trap). Electronic sensors permanently monitor the absorption capacity of the particulate filter. Also integrated into the SCRT system are the sensors monitoring NOx. Because the Euro VI standard makes the use of a diesel particulate filter practically unavoidable, the developers had more latitude in optimising combustion design and fuel consumption. Common-rail injection functions at pressures of up to 1,800 bar. This system has been standard at MAN since 2002 and the Euro V, EEV and Euro VI engines are already equipped with third-generation CR systems. Only CR systems with their fully-variable injection control enable the physics balancing act required in order to deal with nitrogen oxides, particulate and consumption at every operating point. Euro VI engines with outputs of 162 kW / 220 hp and up employ a combination of two-stage turbocharging with primary cooling and intercooling of the boost air.The two turbochargers have been combined to form a single compact turbocharger module. Each stage is equipped with a waste gate. This makes it possible to control boost pressure and distribution between the two stages so that the energy of the exhaust gas is used most effectively. The high-pressure stage, a small exhaust turbocharger with waste gate, ensures speedy build-up of boost pressure and thus high pulling-away torque in the lower load and engine-speed range. Even at low engine speeds the high air ratio is produced that is required for combustion with low particulate content. In the upper load and engine-speed range, the low-pressure stage ensures the necessary amount of air and is characterised by especially high efficiency, resulting in very good fuel consumption and combustion with low particulate levels. This turbocharging strategy not only helps the Euro VI engines also produce the pulling power at all engine speeds for which MAN is renowned, it is also consciously based on two separate rugged and reliable turbochargers instead of more complex turbochargers with variable turbine geometry.

The Euro VI engines in the TGL series delivering 110 kW / 150 hp and 132 kW / 180 hp employ single-stage turbocharging at the same high level of efficiency. The basic design of the engine and stroke and bore have not changed. Cooled exhaust-gas recirculation (EGR) has been in series production at MAN since 2000. The recirculation of cooled exhaust gases makes a low peak combustion temperature possible. As a result, fewer nitrogen oxides are formed. Euro VI utilises electronically-controlled EGR, which ensures considerably improved control performance. Thanks to EGR control with its lambda probe, the optimal EGR rate is set for each operating point of the engine even in dynamic conditions. This guarantees a particularly high level of efficiency and economical fuel and AdBlue® consumption. The newly developed SCRT system used for exhaust-gas aftertreatment combines an oxidation catalytic converter, a closed, electronically controlled surface particulate filter and an SCR catalytic converter with AdBlue® injection. MAN has been using the particulate filter component as CRTec® filter since as far back as 2002. AdBlue has a freezing point of minus 11.5 degrees Celsius. For this reason the tank, the supply lines and the AdBlue® dosing module can be heated, ensuring that exhaust gases are properly cleaned even at low ambient temperatures. Euro VI legislation means that on-board diagnosis has to provide several more functions; the electronics now has to permanently monitor the emission values. In the event of a fault, OBD informs the driver by means of a warning indicator. In addition and independently thereof, Euro VI legislation stipulates an NOx control system ("anti-tampering"). This system monitors the SCR system, checking that it is supplied with AdBlue® in the specified amount and quality. If this is not the case, a warning is initially output to the driver. This escalates to a reduction of torque, and in a third step to a speed restriction. Beforehand, i.e. also from a cold start and during light-loading operation, the limit values as per the "Worldwide Harmonized Duty Cycles" must be complied with. Moreover, the emissions must be guaranteed to be stable for 700,000 kilometres or seven years. This shows clearly just how comprehensive the development and product requirements for Euro VI vehicles are.

Simplified, the SCRT system functions as follows. First, an oxidation catalytic converter with a highly efficient precious-metal coating converts the limited constituents of the exhaust gas, HC and CO, to harmless CO2 and H20. The nitrogen oxides are also largely converted from NO to NO2. The surface particulate filter (CRT) that follows traps up to 99 percent of the particulate mass present in the exhaust-gas stream. The soot particles trapped in the CRT filter are catalytically burned using the NO2 produced beforehand and thus converted to CO2. The soot loading on the particulate filter is electronically monitored by sensors. This information helps to control regeneration of the filter. Continuing the process, with the help of the injected reducing agent AdBlue® the SCR catalytic converter reduces the amount of nitrogen oxide to below the Euro VI limit of 0.4 g/kWh. In combination with EGR and turbocharging, the SCR process enables the engine's combustion to be designed for low particulate levels. This made it possible for MAN's engine designers to also realise consumption-optimised combustion. The nitrogen oxides formed during combustion are then treated by selective catalytic reduction with the help of the additive AdBlue®, which is injected as required upstream of the SCR catalytic converter. The last element that the exhaust gas flows through is an ammonia-blocking catalytic converter. This converts any residual amounts of the reduction agent NH3 (ammonia) necessary for the SCR catalytic converter into nitrogen and water.

Regeneration: highest levels of reliability and safety In formulating its regeneration strategy for the diesel particulate filter, MAN paid special attention to maximum operational reliability. Regeneration of the particulate filter takes place automatically during normal operation without any action having to be taken by the driver. This permanently running passive regeneration ensures that the particles (carbon C) trapped by the filter material are converted to CO2 and do not clog the filter. Regeneration in the TGX, TGS and coach is designed to be carried out by a passive SCRT system. In normal driving operation, the system functions at exhaust-gas temperatures at which regeneration permanently takes place. Special regeneration phases or supplementary injection of fuel to raise the temperature are not necessary during normal operation. If the vehicle spends a lot of time idling or is operated in short-distance transport, the system has other modes that enable it to perform regeneration while on the go.

Regeneration: highest levels of reliability and safety In formulating its regeneration strategy for the diesel particulate filter, MAN paid special attention to maximum operational reliability. Regeneration of the particulate filter takes place automatically during normal operation without any action having to be taken by the driver. This permanently running passive regeneration ensures that the particles (carbon C) trapped by the filter material are converted to CO2 and do not clog the filter. Regeneration in the TGX, TGS and coach is designed to be carried out by a passive SCRT system. In normal driving operation, the system functions at exhaust-gas temperatures at which regeneration permanently takes place. Special regeneration phases or supplementary injection of fuel to raise the temperature are not necessary during normal operation. If the vehicle spends a lot of time idling or is operated in short-distance transport, the system has other modes that enable it to perform regeneration while on the go.Whenever necessary, the "Soft Active" mode uses a secondary-injection function of the common-rail system to raise the temperature of the exhaust gas. This is automatic and does not require any action on the part of the driver. As a further option, the system is able to perform idle regeneration, which can be initiated and ended manually by the driver. Here, the engine carries out a special regeneration program that creates the exhaust-gas temperature necessary for degrading the exhaust-gas particles and regenerating the filter. The engine variants installed in the TGL and TGM series are fitted as standard with active SCRT systems for regeneration of the diesel particulate filter and are thus optimally equipped to meet the demands of distribution transport. This system also functions in normal driving operation without a special regeneration program, that is, it functions with the available exhaust-gas temperatures. In the event of additional self-cleaning becoming necessary, the system causes the exhaust-gas temperature to be raised in several stages. The TGL and TGM also permit idle regeneration initiated by the driver. Due to the typical driving cycles in city buses, these vehicles are fitted with fully passive SCRT systems. The Euro VI diesel particulate filter is regenerated at the temperature of the exhaust gas produced by the engine. In every vehicle, an electronic system monitors the controlled process, the protection of the engine and the components of the exhaust-gas aftertreatment system. Regeneration enables the degradation of almost all particulate while the vehicle is being operated. The residue present after several hundred thousand kilometres can be removed by changing the filter element during servicing. The vehicle's service interval calculator recommends the intervals between cleaning, taking into account the operating conditions and the continually monitored exhaust-gas backpressure. Arrangement and structure of the exhaust-gas silencer are designed for time-saving and thus cost-efficient removal and installation by Service outlets.

The Euro VI system in the TGX and TGS series

The new Euro VI exhaust-gas aftertreatment system including the sensors for NOx and exhaust-gas temperatures as well as for monitoring the exhaust-gas flow is completely integrated in the rear silencers of the trucks and coaches. MAN has packaged the Euro VI rear silencer on the right side of the TGS and TGX vehicles. The task of particulate cleaning is taken over by ceramic filter elements with especially large surface areas.MAN has arranged the Euro VI components in compact form. As has been the case up to now, no parts project above the frame top edge, guaranteeing maximum flexibility for mounting bodies. The AdBlue® tank is a separate, heated tank and is located on the left side of the vehicle. MAN designed the AdBlue® tanks this size so one tankful would provide sufficient range for two tankfuls of diesel fuel. All the variants of the exhaust pipe that have been available up to now will continue to remain available for Euro VI vehicles. The new arrangement of the add-on parts means that the same amount of space on the frame is free for tanks on both sides of the vehicle. The Euro VI system in the TGL and TGM series With the advent of Euro VI, SCR is for the first time being installed in TGL and TGM vehicles, where it supplements the proven EGR technology. The basis is formed by the Euro V / EEV engines, which have been produced in series since 2009.

EGR with demand-controlled recirculation rate and the common-rail system with 1,800 bar injection pressure are the backbone of the Euro VI system in the engine itself. The power spectrum ranges from 110 kW / 150 hp to 251 kW / 341 hp. Engines delivering 162 kW / 220 hp and above are fitted with two-stage turbocharging and boost-air intercooling. The TGL and TGM series meet the Euro VI standard by means of a more compact combination of oxidation catalytic converter, particulate filter and SCR, also completely integrated in the rear silencer on the right side. The task of particulate cleaning is taken over by electronically monitored ceramic filter elements. Free installation space on the right side of the vehicle remains unchanged. The AdBlue® tank is a separate, heated tank and is also located on the right side of the vehicle. The size of the AdBlue® tanks for TGL and TGM is similarly designed for two tankfuls of diesel fuel. MAN TGL and TGM trucks enable outstandingly big payloads even in Euro VI and are among the lightest in their class. The Euro VI system makes the four-cylinder vehicles around 100 kg heavier, the six-cylinder vehicles around 150 kg.